JOHN HOPKIN'S RESEARCHERS ARE MAKING 3D PRINTED BONE REPLACEMENTS WITH JUST THE RIGHT MIX OF INGREDIENTS

posted: May 09, 2016.

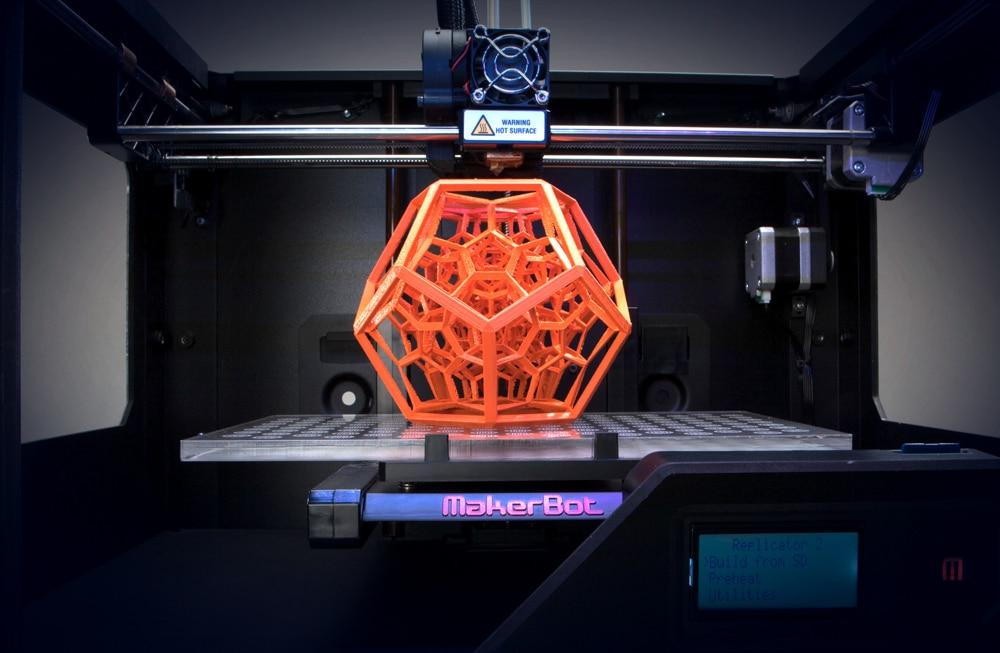

RESEARCHERS FROM JOHN HOPKINS UNIVERSITY IN A RECENT PAPER PUBLISHED ON APRIL 18 STATE, "TO MAKE A GOOD FRAMEWORK FOR FILLING IN MISSING BONE, MIX AT EAST 30% OF PULVERIZED NATURAL BONE WITH SOME SPECIAL MAN-MADE PLASTIC AND CREAT THE NEEDED SHAPE WITH A A 3-D PRINTER. THAT'S THE RECIPE FOR SUCCESS THAT HAS LED INVESTIGATORS TO 3-D PRINTING, OR SO-CALLED ADDITIVE MANUFACTURING, WHICH CREATES THREE-DIMENSIONAL OBJECTS FROM A DIGITAL COMPUTER FILE BY PILING ON SUCCESSIVE, ULTRA-THIN LAYERS OF MATERIALS. THE PROCESS EXCELS AT MAKING EXTREMELY PRECISE STRUCTURES - INCLUDING ANATOMICALLY ACCURATE ONES - FROM PLASTIC, BUT SHELLS PLACED ON PLASTIC SCAFFOLDS NEED SOME INSTRUCTURAL CUES TO BECOME BONE CELLS. THE IDEAL SCAFFOLD IS ANOTHER PIECE OF BONE, BUT NATURAL BONE CAN'T USUALLY BE SHAPED VERY PRECISELY."

BROUGHT TO YOU BY DR. JOHN A. HARDY, OWNER OF ACADEMY FOOT AND ORTHOTIC CLINICS.